There is no doubt weld cleaning machines are ascending in the ranks when it comes to popular methods of stainless steel passivation that are an alternative to hazardous pickling paste.

When you look at any market, and specifically long established methods or practices within those markets, the biggest disruptions are born out of occupational health and safety concerns.

The rise in weld cleaner machine use is driven by the dangers of pickling paste use. Now there is a safer alternative to post weld cleanup.

Post weld cleaning and polishing of stainless steels has been practiced for decades using pickling pastes. These chemical based pickling paste products contain a combination of nitric and hydrofluoric acids which cause serious burn injuries when in contact with the skin. They are primarily used to post weld clean stainless steels and can be applied by brush or by a spray on process. Lower viscosity formulations may reduce the risk of spatter but the best safety procedures always come undone by a series of minor failures and mostly caused by ignorance of the danger these products pose.

To avoid workplace injuries and their subsequent workcover fines, compensation payouts employers are now looking to alternative methods of post weld finishing as part of their risk and hazard reduction processes. The most common approach to improve safety in the work place is the switch to an electropolishing process where possible. Electropolishing machines, also called weld cleaners operate by passing an electrical charge of relatively low voltage between workpiece and brush whilst in the presence of an acidic solution such as phosphoric acid.

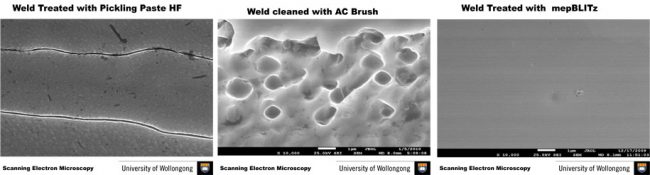

When weld cleaning occurs in stainless steels the electropolishing process dissolves the microscopic high points of the materials whilst removing iron selectively which results in both an increase density of chromium and a smooth surface that prevents bacterial contamination due to the smooth surface.

Electropolishing is often described as electroplating backwards, the key however is to remove the microscopic high points at a much faster rate than the low points or valleys. In the image above, experiments conducted for Metal Science by the University of Wollongong shows the surface finish after using pickling paste (left), an AC brush (centre) and a DC brush powered by the mepBLITz i5 (right). The smooth surface on the right image shows the advantage of electropolishing.

The below text is sourced from the test results on the Easykleen website

“The excellent corrosion resistance of stainless steel can only be achieved if proper cleaning and finishing operations are carried out after any fabrication process as there will have been damage to the surface condition. The corrosion resistance of stainless steel arises from a chromium oxide film that forms a protective layer naturally on the surface of the steel. The chromium oxide film is extremely thin, a few angstroms, but strongly adherent and chemically stable which is commonly referred to as ‘passive’. The film is formed when chromium reacts with oxygen. The film may be described in chemical terms as a Chromium iii oxide (Cr2O3 )”

Tokentools have expanded their range of weld cleaning machinery and have sourced the best products available on the Australian market. The EasyKLEEN range of weld cleaner electropolisher machines is manufactured in Australia and offers the most comprehensive industry warranty up to 10 years.

Tokentools have expanded their range of weld cleaning machinery and have sourced the best products available on the Australian market. The EasyKLEEN range of weld cleaner electropolisher machines is manufactured in Australia and offers the most comprehensive industry warranty up to 10 years. The machines we sell are models Easykleen TEC Brush, Easykleen Plus Brush, Easykleen Pro S-10, Easykleen Pro S-15, mepBLITz DC i5, mepBLITz electropolisher bath accessory.

You may view the range of machines (link here) that we stock

The range of weld cleaning chemicals spans from food safe PH neutral right up to highly acidic phosphoric acid. The fundamental difference boils down to acidity and the more acidic your weld polishing chemical is, the faster you can complete the process. The full range of electropolisher chemicals is here

Weld cleaner Brushes are made from carbon fiber and have been developed by Metalscience to be long lasting and capable of handling the current flow when in use. Brushes are made to suit each of the machines so when looking to replace a brush simply select the filter on the brush page that matches your weld cleaner and the appropriate list of carbon fiber brush will display. The complete weld cleaner brush section is here.