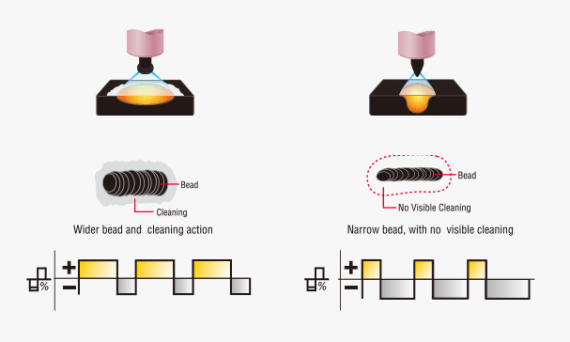

The Key Difference Between AC DC Currents in GTAW Tig Welding

AC current is used for aluminium and it’s alloys. When electrons flow from the workpiece to the positively charged tungsten during the cleaning half cycle, they remove the oxide layer from the surface of the aluminium by blowing it off from beneath and the gas shield of inert argon prevents new oxide forming thus allowing the molten pool of pure aluminium to fuse.